Welcome to Shandong Eterne Machinery Co.,Ltd. Official website

Release date:2024-05-20

Placer gold refers to gold that is formed from rock gold in mountains washed away by rivers and separated from gold and quartz veins. Because this type of gold is as fine as sand, it is called placer gold. Placer gold is easy to mine, but the rock gold mining process is relatively complex and arduous. Generally, only a ton of ore can be mined to extract a few grams of gold. There are many methods for prospecting for placer gold, and there are 5 commonly used methods: ① natural heavy sand method, ② engineered heavy sand method, ③ old mining survey, ④ geological and landform analysis, ⑤ new geophysical and aviation technology methods. There are two main methods of mining placer gold deposits: open-pit mining and underground mining. According to the structural characteristics and the development of geotectonic structures, four metallogenic types of placer gold deposits with similar parameters can be divided.

Exploration methods

Geological factors such as the extension scale, shape, thickness stability and uniformity of distribution of main components of the main ore bodies are used to classify exploration types in order to reasonably determine the density of exploration projects, so as to effectively explore reserves at all levels. There are various geological factors and their combinations in various placer gold deposits and various ore bodies of the same deposit or even different parts of an ore body. The classification of exploration types and the determination of the density of exploration projects are generally based on the main ones that occupy most of the reserves in the deposit. The geological factors of the ore body are considered.

Based on the above classification principles, the exploration types of placer gold deposits are divided into the following three categories:

1. The main ore body has a simple shape, large extension scale, stable thickness, uneven distribution of placer gold, flat floor and small slope. Larger floodplain placer gold mines and coastal placer gold mines mostly belong to this type, such as the Hengkou River floodplain placer gold mine in Shaanxi Province and the Dalahan River floodplain placer gold mine in Heilongjiang Province.

2. The shape of the main ore body is relatively simple, with medium extension scale, little change in thickness, very uneven distribution of placer gold, relatively flat to uneven bottom plate, and large gold grains and contiguous bodies of gold and gangue minerals. River placer gold deposits with flat floors or karst bases, as well as larger branch valley placer gold deposits and terrace placer gold mines, mostly belong to this type.

3. The extension scale of the ore body is small, the shape is complex, the thickness changes greatly, the floor is uneven and tilted greatly, the distribution of placer gold is extremely uneven, and there are more large grains of gold and conjoined bodies of gold and gangue minerals. Smaller karst-filled placer gold deposits, residual alluvial, slope deposit, alluvial placer gold deposits and branch valley placer gold deposits mostly belong to this type, such as the Xicaiyuan residual slope deposit gold deposit in Inner Mongolia Autonomous Region.

Placer gold mining

There are two main methods of mining placer gold deposits: open pit mining and underground mining. Underground mining is rarely used in our country and will not be introduced here.

Placer gold open-pit mining is divided into three categories according to the mining machinery used:

Gold dredger mining method (referred to as "ship mining"): The gold dredger mining method refers to the method of using the bucket on the Caijinchuang to excavate the materials from the river bottom onto the ship, and using the trommel screen on the ship for screening. The gold dredge's deepest digging depth is 20 meters outside.

2. Engineering machinery mining method (referred to as "machine mining"): refers to the use of mechanical shovels, bulldozers, scrapers, loaders and other engineering machinery to excavate and load mineral rocks, and use belt conveyors, truck scrapers, loaders, etc. to transport Placer gold deposits are mined by mechanical transportation to gold wash plant, vibrating screens or trommel scrubber for screening.

3. Hydraulic mechanical mining method (referred to as "water mining"): It is a continuous production process that uses mechanical equipment such as water guns, sand pumps, and water pumps to use the same water flow to complete flushing, transportation, washing, and tailings disposal in sequence.

Placer gold beneficiation method

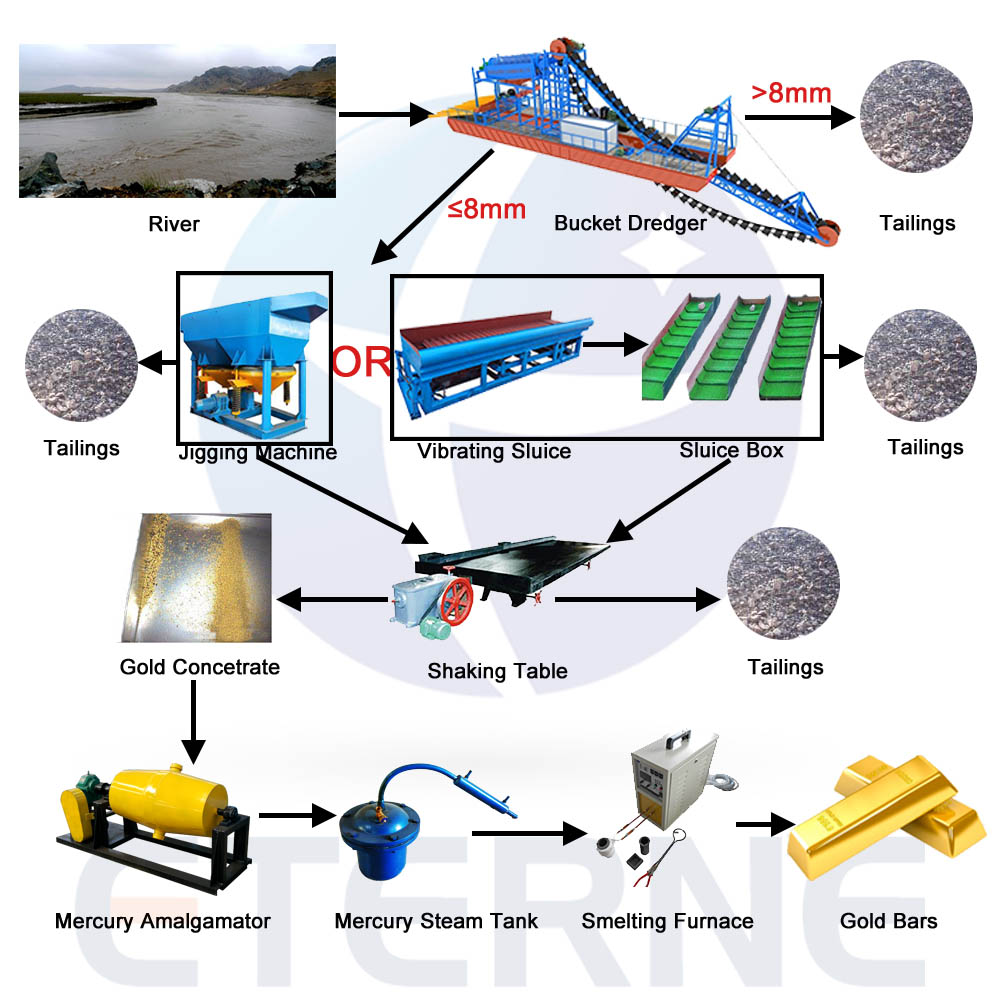

The placer gold ore washing plant uses a jig as the roughing equipment for placer gold ore, and the shaking table as a concentrating equipment for selecting the rough concentrate of the jig. The jig is used in conjunction with the shaker to complete the washing and extraction of placer gold ore.

The main method for washing and extracting gold from placer gold mines is gravity separation. Since gold is in a free state in placer gold mines, and the difference in specific gravity between gold and sand is also very obvious, gravity separation is used to extract gold from placer gold mines. It is the most ideal and efficient method. In the placer gold beneficiation process, the jig is generally used as a roughing or sweeping equipment, while the shaker can only be used as a concentrating equipment. The general placer gold beneficiation process is screening-jigging-shaking table-mercury amalgamation. There are also places where low-grade placer gold ore beneficiation uses chutes as roughing equipment, jigs as sweeping equipment, and mercury amalgamation cylinders or shakers as concentrating equipment. In fact, the mineral processing technology and mineral processing equipment configuration of placer gold mines need to be determined according to the specific properties and characteristics of the ore. Not all placer gold mines can obtain the best washing by using the same mineral processing technology and mineral processing equipment. Therefore, it is recommended that you choose a professional manufacturer and let professional engineers equip you with mineral processing processes and equipment.

Copyright © 2018-2023 Shandong Eterne Machinery Co.,Ltd. technical Support:Aision