Welcome to Shandong Eterne Machinery Co.,Ltd. Official website

Your current location:Home>>Products>>Dredging Equipment>>Cutter Suction Dredger

Classification:Cutter Suction Dredger

Contacts:Lily Su (Director)

HP/Whatsapp:+86 187 6515 4897

Product Introduction

1)Reliable hydraulic system with self-protection, high efficiency and low cost.

2)Simple, rapid assembly and dismantling, a good underwater dredging machine.

3)We can produce 4"inch to 24"inch dredgers with max. dredging depth 25m. The dredger can be customized.

4)Has passed ISO9001, CE ,CCS certificate & The Certification of the Survey.

5)Adapt submerged arc welding technology, strong stability and beautiful in design.

6) Special marine steel plate, strong & durable.

7) Pump & gear box combined together, reduce the maintenance.

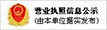

Specification Of 18 inch Cutter Suction Dredger | |||||||

ET CSD200 | ET CSD250 | ET CSD300 | ET CSD400 | ET CSD450 | ET CSD600 | ET CSD650 | |

Dredger body | |||||||

Total Length | 26m | 27m | 29m | 33m | 36m | 40m | 43m |

Full loaded draft | 0.7m | 0.8m | 0.9m | 0.9m | 1.2m | 1.2m | 1.5m |

Dredging data | |||||||

Max.dredging depth(m) | 8 | 10 | 12 | 15 | 15 | 20 | 30 |

Water flow(m3/h) | 600 | 1000 | 1500 | 2200 | 3000 | 5500 | 7000 |

Max.dredging depth(m) | 8 | 10 | 12 | 15 | 15 | 17 | 17 |

Discharge diameter(mm) | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 |

Suction Pipe Dia.(mm) | 250 | 300 | 350 | 450 | 500 | 650 | 700 |

Discharge Pipe Dia.(mm) | 200 | 250 | 300 | 400 | 450 | 600 | 650 |

Cutter head | |||||||

Cutter head diameter(mm) | 650 | 850 | 950 | 1200 | 1200 | 1500 | 1800 |

Devices | |||||||

Amount power(kw) | 190 | 300 | 450 | 760 | 1007 | 2300 | 2800 |

Winch(hydraulic) | |||||||

Ladder winches | JC-3000 | JC-4000 | JC-4000 | JC-6000 | JC-6000 | JC-10000 | JC-12000 |

Swing winch | JC-3000 | JC-4000 | JC-4000 | JC-6000 | JC-6000 | JC-8000 | JC-10000 |

Pontoons | |||||||

Quantity | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

Spuds length* diameter(mm) | 8600*273 | 11000*300 | 13000*350 | 15000*377 | 17000*450 | 17000*550 | 17000*600 |

Spuds weight/pic | 900kg | 1500kg | 2000kg | 2500kg | 3900kg | 4500kg | 5000kg |

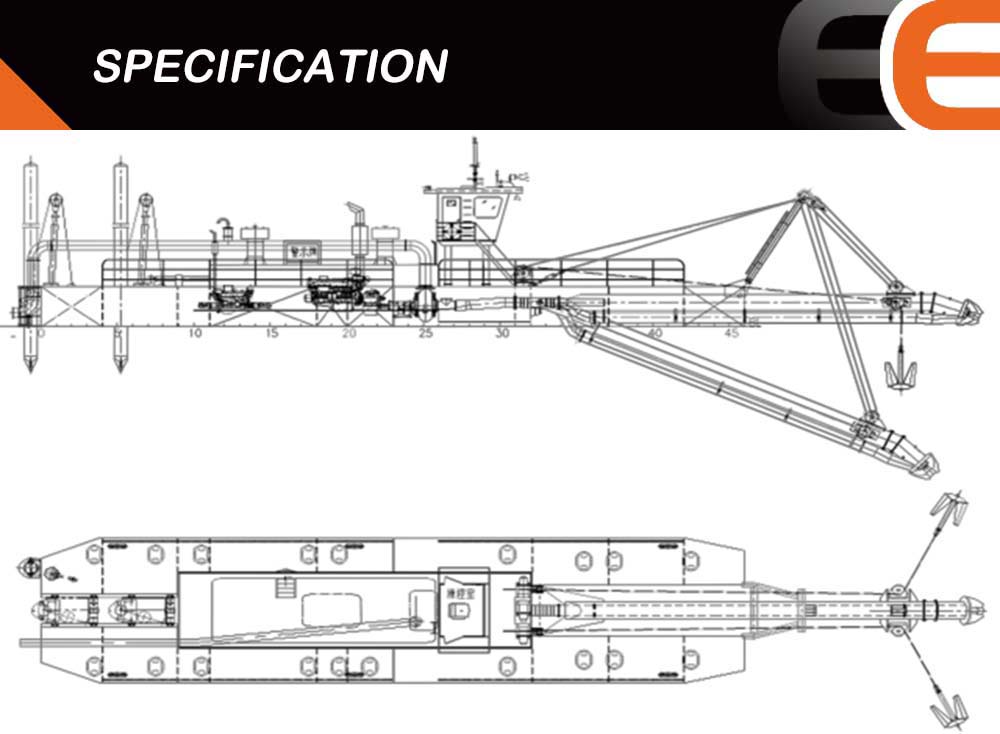

Eterne Company has taken the lead of passing lSO9001:2008 lnternational Quality System Certification & theGeneral Ship Production Enterprise Technical Condition Evaluation Certificate issued by ZC,CCS to provide our customers with dredger products of high standard & quality. Our design has been continuously improved using the latest technological developments, as well as taking into account feedback from our customers. All to further improve operational efficiency and sustainable performance.

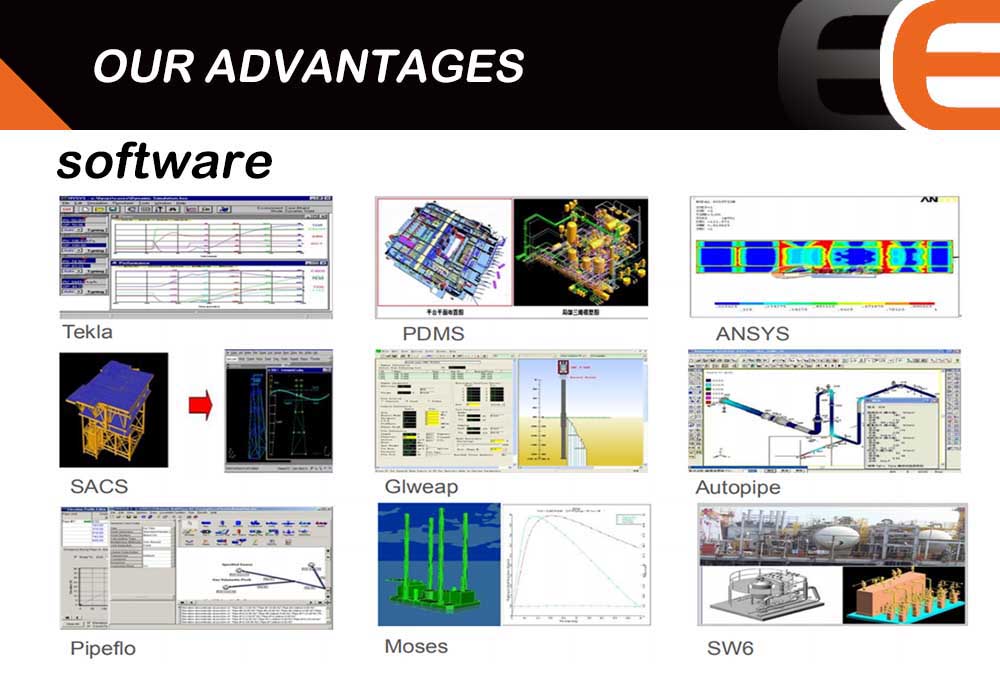

1.Electric cutter suction dredger

We have electric dredger for you to choose.One of the main advantages of ETERNE electric dredgers is their environmental friendliness, as they do not use fuel to burn, reducing emissions. With reduced noise and flexible operation, it is suitable for working conditions such as reservoirs and small rivers that can provide power.

2.Bucket-wheel system

The bucket-wheel device is very suitable for construction on hard terrain. The torque of the bucket wheel is twice that of the same power cutter head, and it can perform better construction when facing hard mud layers. The front end of our cutter suction boat is a bolt design, which can realize the interchangeability of cutter suction head and bucket wheel device. If the soil is relatively soft, it can be switched to a cutter head excavation device.

3.Work boats

ETERNE cutter suction dredger can be equipped with work boats, which can provide various auxiliary functions for the cutter suction boat, such as anchoring, transporting materials, etc. Our workboats come in a variety of styles, can be disassembled and assembled, and can be transported by car or container.

4.Dredger with Trolley

Traditionally, cutter suction boats need to constantly change the location of the cutter suction during operations in order to fully clean the target area. With the trolley system, by reducing the time for replacing piles, the cutter suction ship equipped with the trolley system can complete more workload in the same time. This technological improvement can increase the working efficiency of cutter suction boats by 5% to 50%, depending on the operating conditions and working methods.

5.Anchor rod system

The bolt system is one of the important factors that directly affect production. The function of the bolt system during the construction process is to move the bolt forward to meet the requirements of reamer lateral movement excavation. Different dredgers have different anchoring methods. The advantages are The operation is convenient and the anchoring speed is fast.

6.The bottom of the operating room is designed with glass

This design can facilitate the crew to observe the working conditions of the front winch and reamer head, and can also prevent the winch winding problem.

Copyright © 2018-2023 Shandong Eterne Machinery Co.,Ltd. technical Support:Aision Network